Order your sallea scaffolds

Get access and test sallea’s purely plant-based, high-protein (>80%) and functional scaffolds. The ProteinPURE line is optimized in texture for beef and pork applications.

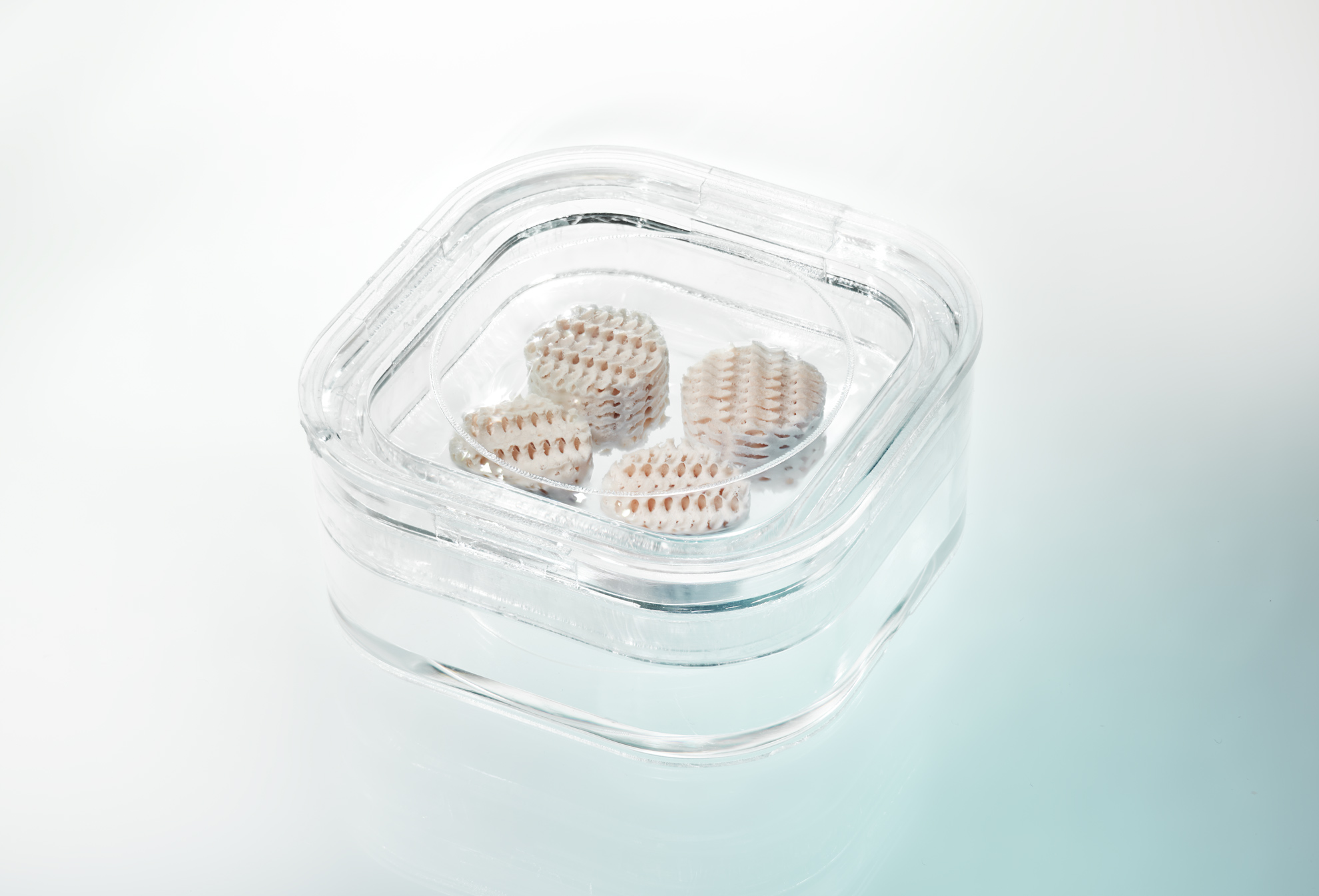

ProteinPURE starter kit

Set of 24 scaffolds, containing 3 different protein compositions, based on soy, lentil and pea (8 of each).

Single protein starter kit

Not interested in testing different proteins because you already have a preferred one?

Starter kits from one single protein type are available on request.

Haven’t found what you’re looking for?

Interested in partnering with us, or learning more about sallea’s scaffolds? Do not hesitate to contact us!